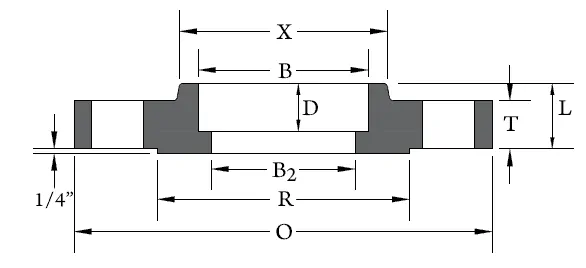

Socket weld flanges are a less common but equally effective connection for flanges which require less overall available space than a traditional weld neck flange, with a counterbore in the center to allow for a clean weld of pipe into the socket.

Usually furnished in smaller nominal pipe sizes, these make an excellent alternative to weld necks and slip ons when necessary. An assembly with limited space may be an instance in which a socket weld is selected, provided the pressure class is comparatively low and the fluid is not corrosive or for extremely high temperature service.

These socket flanges connect to square end pipe with a fillet weld at the ID of the hub of the socket, as the pipe is designed to sit almost flush against the counter bore of the flange. The expansion gap between the end of the pipe and the counter bore leaves just enough space for the welder to adjust the pipe within the connection. It is important to note that a butt weld pipe connection is not recommended for suiting to a socket counter bore connection when a square end pipe connection is possible.

United Oilfield provides a large inventory of socket weld style flanges, with the majority of stock representing the carbon and stainless family in sizes 6” and below. For larger nominal sizes, it is safe to assume that a socket weld flange would be made to order for your application, due to the fact that larger pipe size assemblies will typically call for a slip on or weld neck connection.

RF Type

An RF socket weld flange features a small raised portion around the flange bore, serving as a seat for the gasket, promoting effective sealing.

RTJ Type

The RTJ type entails a groove on the raised face surface, allowing for the placement of a gasket ring to enhance sealing performance.

Socket Weld Flange vs. Slip-On Flange

A socket weld flange closely resembles a slip-on flange, but it distinguishes itself by having a shoulder within the inner bore.